DESCRIPTION

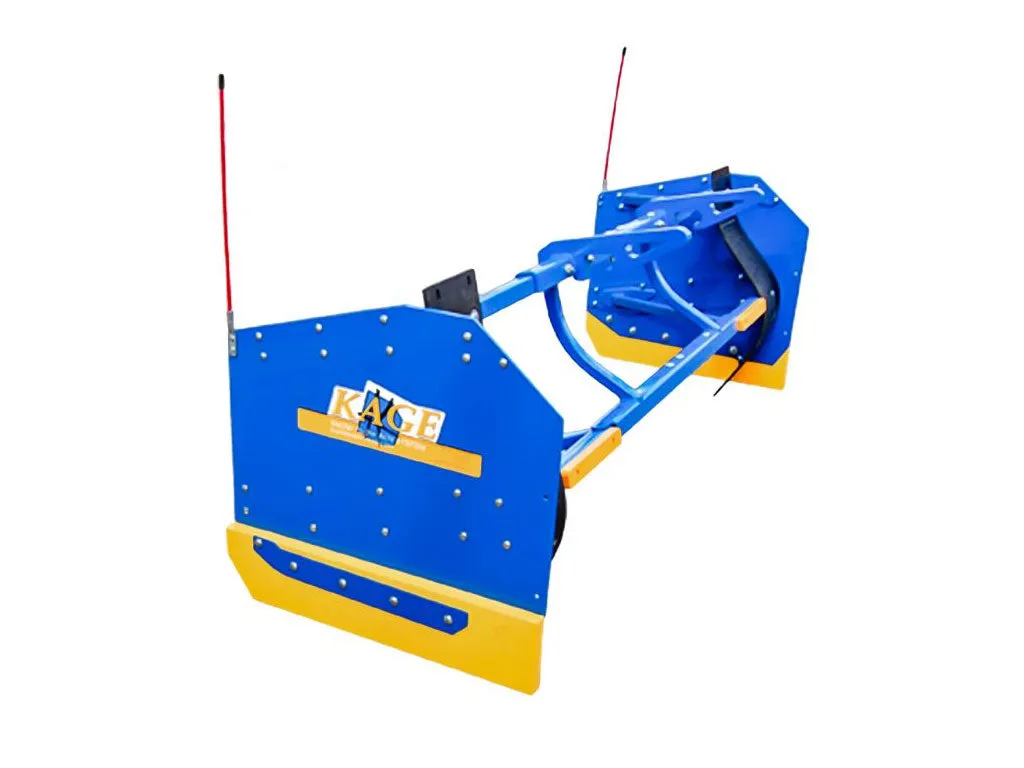

Seamless Transition from Snow Plow to Box Plow

The SNOWKAGE box hooks onto a skid steer snow plow to instantly create a revolutionary containment system. This is done in seconds without leaving the cab – no pins, bolts, or hinges. The KAGE system takes the advantages of a snow plow and a pusher box and combines them into one fast and seamless operation. Operators can windrow or backdrag with the plow normally, then grab the SNOWKAGE box to push out their piles or windrows. Then they can go back to plowing – without leaving the cab. The KAGE system reduces plowing frustrations and hassles. The KAGE system reduces plowing times by 25-50%.

-

Snow Scraping

With the KAGE box attached, the trip edge mechanism of the plow still operates normally. Not only does the trip edge work normally, but so does the cutting edge! The scraping ability of the plow is not hindered by the ‘shoes’ of the SNOWKAGE. This means that you are always scraping down to asphalt in one pass.

-

Snow Plow Angle Function

Use the angle function of the plow while you are pushing. This means that you have a huge advantage over fixed snow pushers in that you can maneuver the load around turns without losing half of it! -

Snow Stacking

The KAGE system is great for cleanup operations, as well as break-out during a heavy snow fall. The applications for the KAGE system combined with the skid steer versatility are virtually endless. In contrast, fixed snow pushers reduce skid steer efficiency and versatility. The normally wide range of sites that skid steers can be used at is greatly diminished, and little things like cleanup along curbs becomes a chore. When KAGE box is dropped off, there is no change to the performance of the snow plow. Can it stack snow? Why yes, of course. In fact it will stack higher and faster than a pusher or bucket because you have more reach and don’t have to ‘dump’!

-

The Blade - Tri formed box for strength

The KAGE Moldboard has a plow structure like no other in its class. The full length Tri-Formed Box structure gives it the most torque resistance and rigidity. Designs like this have been used in the highway plows for years. We take skid steer plowing seriously. Even the moldboard sheet itself is no run-of-the-mill mild steel. No this is 10ga GRADE 50, which among other things has a higher tensile strength, meaning it is harder to dent and tear, prolonging the life of the finish and plow itself. -

The Blade - Powder coated

Powder Coated Snow Plow Blade Baked on powder coat and primer at 400 degrees safeguards all of the steel components, and keeps the Blade looking great for years. We don’t like the look of rust streaks or deteriorating pockets of corrosion, and we guess neither do you, so we eliminate all of that through a proprietary method of applying seam sealer to all un-welded joints prior to the finish getting baked on. This substantially increases the life of the entire finish and overall long lasting quality appearance. Not to mention our two-tone powder process that gives you the striking KAGE Blue and black combination, signifying Lasting KAGE Quality. -

The Blade - 9" plow trip edge

The Blade features a tall, 9″ safety trip-edge standard. This prevents accidental damage when encountering hidden obstacles by tripping back 68 degrees. Powered by four compression style return springs and pivoting on 7 total 1 inch trip pins, it trips when you need it, and stays put when you don’t. -

The Blade - Blade down pressure

Snow Plow Down PressureDown pressure? Bring it on! Trip edges like this are meant to take the abuse so common to skid steer plowing -

The Blade - Aggressive plow angle

The Attack Angle is an aggressive 65 degrees so that it scrapes cleanly – forward and backwards. Mounted onto the trip edge is a High Carbon steel cutting edge, 6 inches tall, 5/8 inches thick. Angle plowing with a skid steer at low speed? Absolutely! No question that this is efficient, and it’s made even better with the severe 35 degree max angle that the plow can achieve. This is more productive and efficient than plowing with trucks in many situations! -

The Blade - Cutting edge

Our cutting edges are also a result of the highway department standards, and will fit up with any ‘standard highway punch’ design, available almost anywhere. No-one wants more downtime, so just replace the edge as needed – no need to move, rotate, flip or flop! -

Hydraulic system

First, we put protective sleeves on all of the hoses; standard. Next we include a Stucchi APM Series Male and Female Coupling that will connect by hand with residual pressure of 300 bar or 2900 psi locked in the hydraulic circuit. It will connect with residual pressure without releasing any fluid into the environment. The mating circuit will need to be without residual pressure. Mobile equipment & attachment tools where exposure to the sun,or temperature change causes pressure to develop due to thermal expansion of trapped fluid. Any application where static pressure can get locked into the system.

Finally, this system is completed with fluid restrictors, an adjustable hose-placement tie-down block and two Nitro Rod plow cylinders. This robust system complements the rugged features and operation of this system in any environment old man winter can produce.

-

Blade Oscillation

Well the next thing is oscillation, this prevents situations when your blade doesn’t stay flat on the plowing surface, whether due to uneven pavement, or improper boom adjustment. The KAGE Blade always stays flat on the plowing surface, from tip to tip whether fully angled or straight. Even with down pressure applied! Simple for operators, just drop and go. You don’t have to worry about one side digging in as you angle or drive over bumps. -

The box - SNOWKAGE Transforms Simple Blade Into Box Plow

So simple, yet so genius. The simple design of the SNOWKAGE gives it a bullet proof structure that befuddles the destructive tendencies so many snow removal operations can produce. -

The box - Flexible Polyurethane Skids

Polyurethane skids are flexible, rather than rigid steel shoes. Finally, something that doesn’t get bent up! They also feature 4 slots in the rear that allow the skid to self-adjust upwards as the cutting edge of the plow becomes worn. This ensures that the plow is always scraping and cleaning like it should. -

The box - Low maintenance

Every detail of the SNOWKAGE flows right into the overall theme of low maintenance and simplicity. The polyurethane bumpers protect the finish, while the pre-punched 10 inch wide snow catches prevent spillage while pushing. -

The box - replaceable side panels

Replaceable side panels are standard and just bolt on easily in case of replacement. -

The box - SNOWKAGE Frames

SNOWKAGE Frames: 6ft solid weldment, 8ft – 10ft adjustable.

SK72 Frame – 6ft solid weldment

SK2011 Frame – 8-10ft adjustable

VIDEOS

SPECIFICATIONS

| For Machines Starting at 5,000 lbs | SK72 |

|---|---|

| Overall Height | 40″ |

| Overall Width | 80″ |

| Replaceable Side Panels | Yes |

| Hook Thickness (Skid-steer Model Only) | 1.5″ |

| Replaceable Poly Skids | 36″ x 9.75″ x 1.5″ |

| Weight | 366 lbs |

| Machine Size Recommended | 5,000 lbs |

| Overall Width at 35 Degree Angle | 85.8″ |

| Total Weight of Kage System (Blade Box) | 1,272 lbs |

| For Machines Starting at 5,000 lbs | SB96 |

|---|---|

| Blade Width | 8′ |

| Blade Width at Full Angle | 79″ |

| Oscillation (Degrees/Inches) Each End | 6°/10″ |

| Moldboard Radius | 15.5″ |

| Moldboard Gauge / Steel Grade | 10 ga. / Grade 50 |

| Trip Springs | 4 |

| Cutting Edge High Carbon | 5/8″ x 6 |

| Cross-Over Relief Valve | Standard |

| Pivot Frame Length | (31″) |

| Machine Size Recommended | 6,000 lbs |

| Weight | 1031 lbs |

| Cylinders (2) | Nitro 1.5″ |

| Blade Height | 31.125″ |

| For Machines Starting at 5,000 | SB108 |

|---|---|

| Blade Width | 9′ |

| Blade Width at Full Angle | 88.5″ |

| Oscillation (Degrees/Inches) Each End | 6°/11.25″ |

| Moldboard Radius | 15.5″ |

| Moldboard Gauge / Steel Grade | 10 ga. / Grade 50 |

| Trip Springs | 4 |

| Cutting Edge High Carbon | 5/8″ x 6 |

| Cross-Over Relief Valve | Standard |

| Pivot Frame Length | (31″) |

| Machine Size Recommended | 6,500 lbs |

| Weight | 1087 lbs |

| Cylinders (2) | Nitro 1.5″ |

| Blade Height | 31.125″ |

| For Machines Starting at 5,000 lbs | SB120 |

|---|---|

| Blade Width | 10′ |

| Blade Width at Full Angle | 98.25″ |

| Oscillation (Degrees/Inches) Each End | 6°/12.5″ |

| Moldboard Radius | 15.5″ |

| Moldboard Gauge / Steel Grade | 10 ga. / Grade 50 |

| Trip Springs | 4 |

| Cutting Edge High Carbon | 5/8″ x 6 |

| Cross-Over Relief Valve | Standard |

| Pivot Frame Length | (31″) |

| Machine Size Recommended | 7,000 lbs |

| Weight | 1147 lbs |

| Cylinders (2) | Nitro 1.5″ |

| Blade Height | 31.125″ |

| For Machines Starting at 5,000 lbs | SB144 |

|---|---|

| Blade Width | 12′ |

| Blade Width at Full Angle | 119″ |

| Oscillation (Degrees/Inches) Each End | 6°/15″ |

| Moldboard Radius | 15.5″ |

| Moldboard Gauge / Steel Grade | 10 ga. / Grade A36 |

| Trip Springs | 8 |

| Cutting Edge High Carbon | 5/8″ x 6 |

| Cross-Over Relief Valve | Standard |

| Pivot Frame Length | (31″) |

| Machine Size Recommended | 8,500 lbs |

| Weight | 1,541 lbs |

| Cylinders (2) | Nitro 2″ |

| Blade Height | 31.125″ |

| For Machines Starting at 5,000 lbs | SK72 | |

|---|---|---|

| Overall Height | 40″ | |

| Overall Width | 80″ | |

| Replaceable Side Panels | Yes | |

| Hook Thickness (Skid-steer Model Only) | 1.5″ | |

| Replaceable Poly Skids | 36″ x 9.75″ x 1.5″ | |

| Weight | 36

|

|

| Machine Size Recommended | 5,000 lbs | |

| Overall Width at 35 Degree Angle | 85.8″ | |

| Total Weight of Kage System (Blade Box) | 1,272 lbs |

| For Machines Starting at 5,000 lbs | SK96 |

|---|---|

| Overall Height | 40″ |

| Overall Width | 104″ |

| Replaceable Side Panels | Yes |

| Hook Thickness (Skid-steer Model Only) | 1.5″ |

| Replaceable Poly Skids | 36″ x 9.75″ x 1.5″ |

| Weight | 442 lbs |

| Machine Size Recommended | 6,000 lbs |

| Overall Width at 35 Degree Angle | 105.4″ |

| Total Weight of Kage System (Blade Box) | 1,473 lbs |

| For Machines Starting at 5,000 lbs | SK108 |

|---|---|

| Overall Height | 40″ |

| Overall Width | 116″ |

| Replaceable Side Panels | Yes |

| Hook Thickness (Skid-steer Model Only) | 1.5″ |

| Replaceable Poly Skids | 36″ x 9.75″ x 1.5″ |

| Weight | 442 lbs |

| Machine Size Recommended | 6,500 lbs |

| Overall Width at 35 Degree Angle | 115.3″ |

| Total Weight of Kage System (Blade Box) | 1,529 lbs |

| For Machines Starting at 5,000 lbs | SK120 |

|---|---|

| Overall Height | 40″ |

| Overall Width | 128″ |

| Replaceable Side Panels | Yes |

| Hook Thickness (Skid-steer Model Only) | 1.5″ |

| Replaceable Poly Skids | 36″ x 9.75″ x 1.5″ |

| Weight | 442 lbs |

| Machine Size Recommended | 7,000 lbs |

| Overall Width at 35 Degree Angle | 125.2″ |

| Total Weight of Kage System (Blade Box) | 1,589 lbs |

| For Machines Starting at 5,000 lbs | SK144 |

|---|---|

| Overall Height | 40″ |

| Overall Width | 150″ |

| Replaceable Side Panels | Yes |

| Hook Thickness (Skid-steer Model Only) | 1.5″ |

| Replaceable Poly Skids | 36″ x 9.75″ x 1.5″ |

| Weight | 477 lbs |

| Machine Size Recommended | 8,500 lbs |

| Overall Width at 35 Degree Angle | 145″ |

| Total Weight of Kage System (Blade Box) | 1,983 lbs |

Cart(

Cart(